Sealing and Stabilization Systems for Flood Protection Systems

For dike, levee, seawall or protection dam

The recurrent extreme flood events in recent years on the Elbe, Danube and Rhine have shown that the stability of many old dikes and levees is at risk.

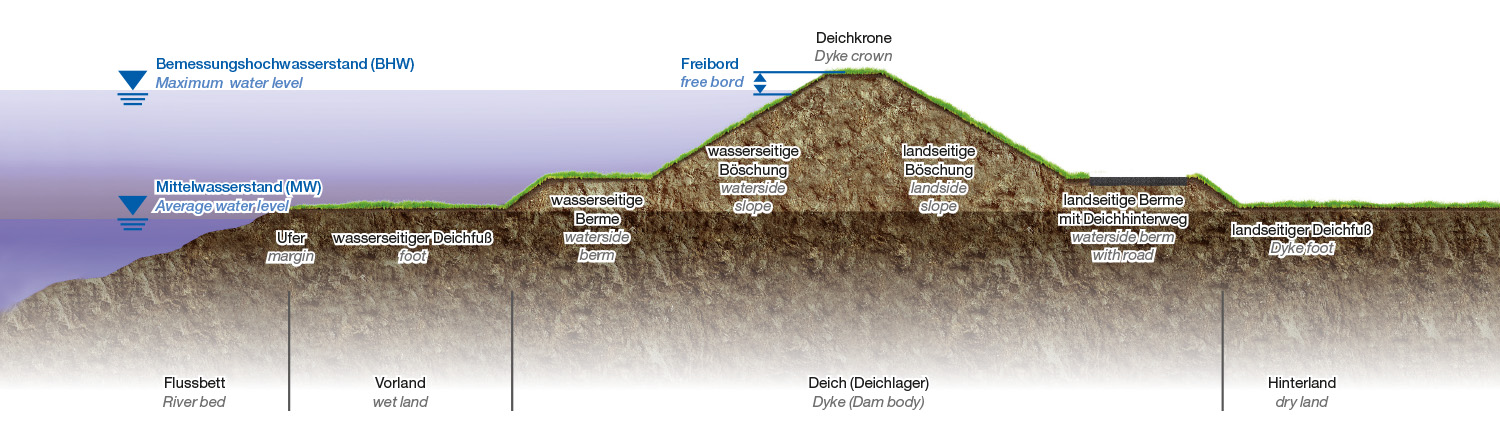

During the actual flood, in case of insufficient compaction or inadequate maintenance, the flow pressure originates faults inside the dike body by loosening grains from within the soil structure (suffusion). In extreme cases, erosion streams form (piping) and eventually trigger erosion shear failure leading to the condition of failure of the levee or tailing dam.

Suffusion can trigger subsidence of the whole dam, which in extreme high water levels results in premature overflow. Since most levees are not designed to work underneath currents, a general levee failure can be the result from retrogressive erosion.

Under certain conditions, the erosion shear failure as well as the overflow can be averted by massive use of sandbags to increase the dike’s height or its internal proper weight. However this procedure is extremely complex and requires the deployment of large personnel in very short time.

Short-term sealing of the tailing dam in the event of a disaster by usual specialized foundation engineering processes like sheet piling, clay cut-offs, jet-grouting, large diameter pile method or diaphragm walls are usually out of question due to the high risk of instability of the structure by the sole load of the application equipment and the non-immediate effectiveness of the measures taken.

Procedures with the use of a seal by subsurface injection with cement mortar cannot be applied in the event of a significant flow through the dike, due to the dilution of the cement emulsion by moving water flow.

Fast-reacting, slightly flexibilized, strongly expanding injection foam based on silicate resin, contains flame retardants

- Filling of cavities in mining, civil engineering and tunnel construction

- Consolidating rock

- Stopping of water infiltration

- Self-compacting due to high foam factor

Rubber-elastic, 3 C acrylate gel, multi purpose applicable

- Very low viscous

- Very good penetration

- Proven stability of at least 16 years

Filling and Solidifying as an Emergency Measure – Flood Protection

Rubber-elastic, 3 C acrylate gel, multi purpose applicable

- Very low viscous

- Very good penetration

- Proven stability of at least 16 years

Case study: Deep Water Seaport Permanently Stabilized

Sheet piling quay walls of the Jade Weser Port were successfully waterproofed through resin injection. Due to the difficulties in the pressing of 40m long sheet pile elements inevitable major leakages showed up in the joints during the excavation phases of the port basin. These openings had as consequence the wash out of the sand due to waves and tides from within the quay chamber. The problem grew up to unsustainable dimensions after the high tides and the storms in autumn and new year.

The sand washed out of the inner basin would accumulate on the opposite side of the pile curtain and in the long run could interfere with ship traffic. Permanent excavation works were intensively used as corrective measure but also the stability of the sheet piling itself could be compromised as well as the one of the plate supporting piles within the quay area.

Difficult Conditions

The immediate measure from the building JV was to commission a full stabilization of the sand mass with deep injections on the landside, behind the sheet pile curtain. The main problem was the access though the quay concrete plate were the only available openings were in form of 80x80cm passages. It was not possible to make traditional boring due to the fact that underneath the plates there were “discharge chambers” filled with water that allowed the works only via boat on the waterside.

The only alternative was to use manchette pipes (“tubes à manchette”, in short “TAMs”) coupled with press spears that were pushed into the sand down to 18m depth for the injection. To fully saturate the sand, 3 spears were foreseen to every sheet pile chamber. As injection good only an extremely low viscosity polymethyl acrylate gel could be used, considering also the environmental safety of the area. TPH’s RUBBERTITE with DIBt certification for curtain injection and environmentally non-hazardous could be used without any problems.

Permanent Waterproofing

The stabilized and consolidated sand was not washed out from any point of the 1725m long sheet piling of the quay wall and the rubber elastic consistency of the material employed guarantees a permanent closing of all gaps in the joints.