Water-Swelling Rubber

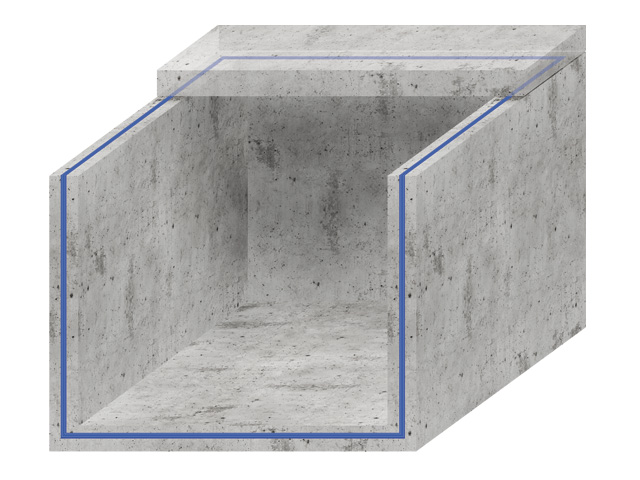

Water-swelling rubber (hydrophilic rubber) is used for sealing of construction joints against pressurized water in reinforced concrete structures. HYDROTITE®, HYDROSEAL and AQUA TACKSEAL® are hydrophilic rubber profiles which are used widely as sealing compounds in structural, civil, construction engineering and tunnel construction. The various hydrophilic rubber profiles stand out especially due to high chemical resistance against acids, alkalis, fuels, mineral oils, organic solvents etc. in addition to its extremely good mechanical properties such as high elasticity and high tear strength. They only differ in the raw material base and the maximum swelling rate.

- Easy processing

- Long-term efficacy

- Also applicable in tidal zones

- High chemical resistance against sewage, manure and chemicals

Recommended Systems

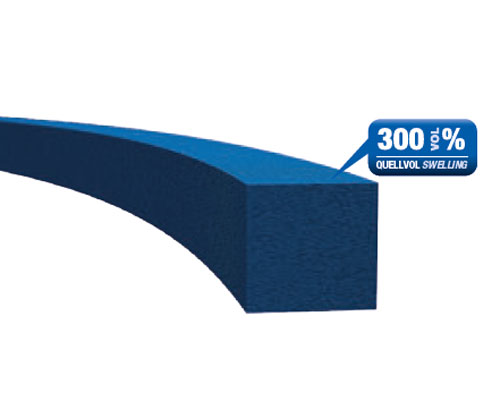

Water-swelling rubber based on polychloroprene

- For construction joints in structural, civil and construction engineering

- High chemical resistance against sewage, manure, chemicals aviation fuel (Jet A-1) and deicer

- Integrated pressure limit for small wall dimensions

Water-swelling rubber based on polychloroprene and EPDM rubber

- For construction joints in structural, civil and construction engineering

- High swelling pressure and volume for massive elements

- For old/new connection

Water-swelling rubber based on polyurethane

- Economical solution for construction joints

- For construction joints in structural, civil and construction engineering

- Made to measure is possible

Water-swelling rubber based on of semi-vulcanised butyl rubber

- For sealing of precast elements, shaft rings, channels as well as drains

- Assimilates automatically to the shape of construction

- For construction joints in structural, civil and construction engineering

- Adhering on concrete, metal, glass and synthetic materials

Equipment

One component, hydrophilic sealing compound for bonding of hydrophilic rubber.

Neoprene adhesive.

Mastic adhesive and sealing compound for gluing on moist surfaces and even under water.

For cleaning substrates and for bonding dusts and other contamination.

For connection and dilatation joints inside and outside and for permanently elastic sealing.

For priming heavily absorbent surfaces such as weathered concrete, brickwork, aerated concrete, eternit, natural stone, etc.

Uses

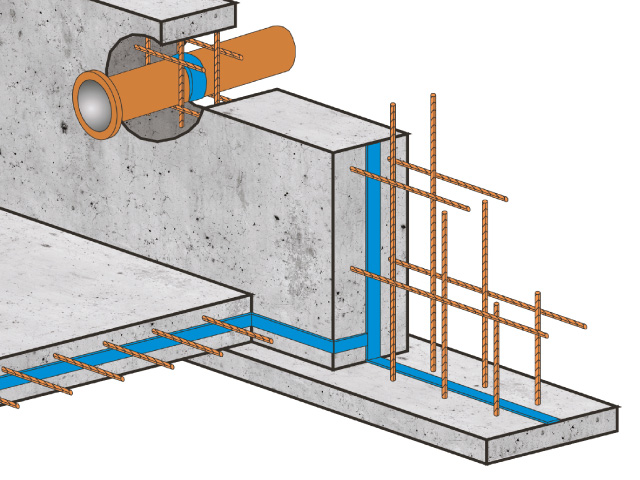

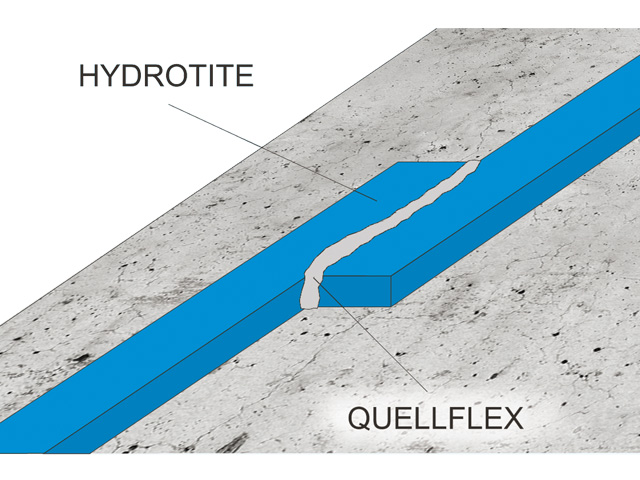

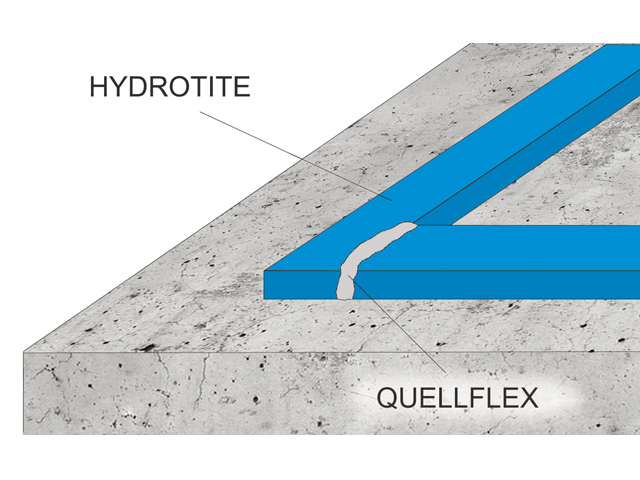

Installation is made in the centre of the reinforcement. Depending on the surface condition, fixing is made by adhering with HF-KLEBER, FIX-O-FLEX or QUELLFLEX®. The sealing of pipe breakthroughs is possible by using HYDROTITE® circular profiles.

The sealing of diafragma joints is possible by using HYDROTITE® circular profiles. Fitting is carried out by knocking the profile in with a pneumatic hammer. Plugging will be made by sealing with FIX-O-FLEX.

In corner areas, the hydrophilic rubber profiles are butt-glued at an angle of 90°. The butt area must be secured by QUELLFLEX®.

Connection of profile endings is done by adhesion of parallel bands by means of QUELLFLEX®.

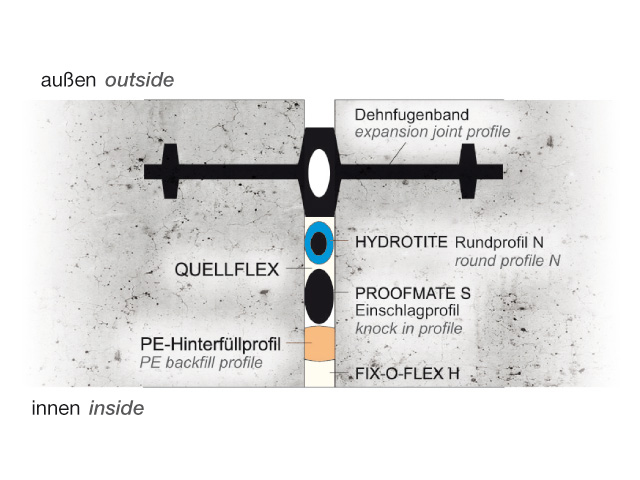

- HYDROTITE® circular profiles with a neoprene core are used for the renovation of expansion joints. The profile is knocked into the joint once it has been cleaned out.

- When selecting the profile diameter, ensure that pre-compression is achieved as soon as the profile is knocked in. You must also ensure that the HYDROTITE® profile is well plugged on all sides (see sketch).

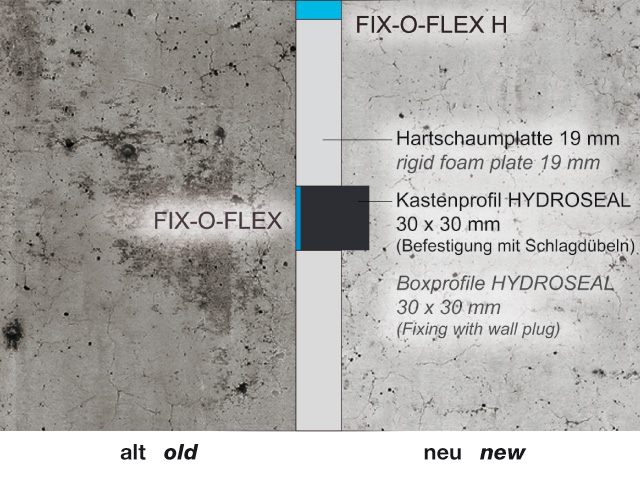

- HYDROSEAL box profiles are used to seal between old and new structures against non-pressurised and pressurised water. Fixing of the hydrophilic rubber takes place on the old structural concrete by gluing with FIX-O-FLEX and additional fixing with dowels.

- The joint is created using rigid foam panels (19 mm thick) so that the HYDROSEAL profile is concreted in around one third of its depth. Joint sealing is carried out permanently elastically by surface-sealing with FIX-O-FLEX H.

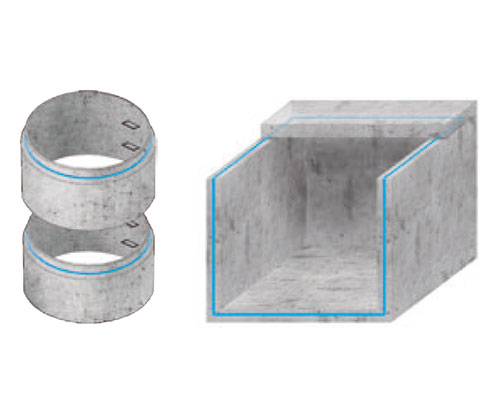

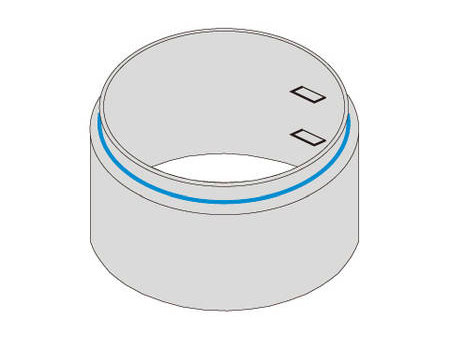

The main use of AQUA TACKSEAL® is the sealing of shaft rings against in-situ groundwater. Shaft rings can be sealed using both sockets and rebates. AQUA TACKSEAL® functions on one hand like conventional sliding ring seals through compression, and on the other hand creates additional sealing through adhesion and expansion pressure.

Assimilates automatically to the shape of construction. Adhering on concrete, metal, glass and synthetic materials.

- High chemical resistance against sewage, manure, chemicals aviation fuel (Jet A-1) and deicer

- Integrated pressure limit for small wall dimensions

- Long-term efficacy

- 30 years of experience