PUR-O-STOP FLEX

1-component highly flexible injection resin based on polyurethane

- Stopping of slight inrushing water

- Simultaneous crack filling according to DIN EN 1504-5

- For filling of cavities ( < 1m3)

- For sealing and solidifying of soil and gravel

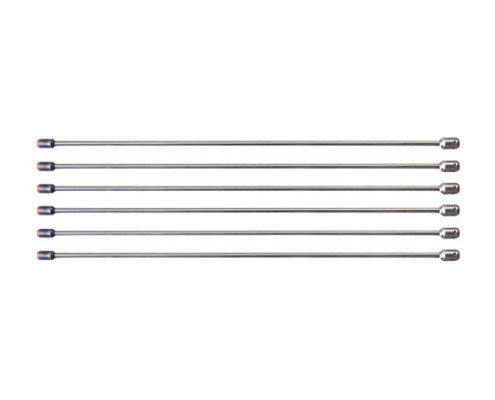

Packer

For grouting acrylate gels, polyurethane and epoxy resins

For grouting in soil, gravel

Plugging / Sealing

Liquid to viscous Polyurethane based adhesive for plugging or fixing adhesion packers

Mineral-based rapid bonding cement for rapid curing and plugging during injection

For sealing off drill holes up to Ø 50 mm as well as big cracks and break outs.

Injection Equipment

Small, light 1-component injection pump for processing of polyurethane and epoxy resins.

Accu driven, 1K injection machine for fast and easy injections at small or middle size jobs.

Cleaner

Effective cleaning agent for the removal of polyurethane and epoxy resins.