PUR-O-STOP

1-component injection resin based on polyurethane

- For stopping running water

- By catalyst addition adjustable reaction time

- For filling of cavities ( < 1m3)

- For sealing and solidifying of soil and gravel

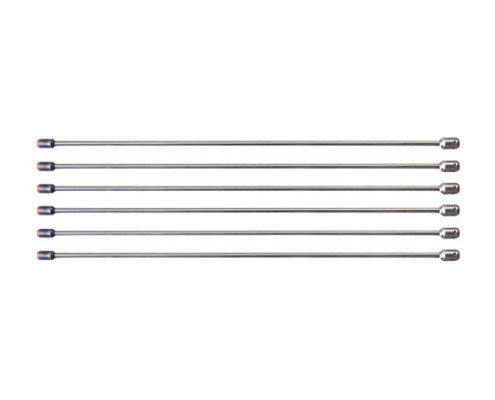

Packer

For grouting acrylate gels, polyurethane and epoxy resins

For grouting in soil, gravel

Plugging / Sealing

Liquid to viscous Polyurethane based adhesive for plugging or fixing adhesion packers

Mineral-based rapid bonding cement for rapid curing and plugging during injection

For sealing off drill holes up to Ø 50 mm as well as big cracks and break outs.

Injection Equipment

Small, light 1-component injection pump for processing of polyurethane and epoxy resins.

2-component injection pump made of stainless steel for the procession of acrylate gels.

Cleaner

Effective cleaning agent for the removal of polyurethane and epoxy resins.