StarrGleis Sil

Especially for stabilization of track gravel

- Universally applicable in railway constructions, regardless of type and moisture of gravel

- Approved by the German Railway Authority

- As protection against ballast shifting and flying ballast

- For easier cleaning of track ballast beds

Mixture of A-and B-Component

Processing temperature

15 – 30°C (substrate temperature)

Viscosity of mixture (23°C)

~ 200 mPas (DIN EN ISO 2555)

Mixing ratio A : B

1 : 1 (parts by vol.)

Reaction Data at 23°C

String gel time

~ 60 s (ASTM D7487)

Final curing

~ 20 min

Properties After Curing

Compressive strength

~ 25 N/mm2 (DIN EN 1219

E-modulus

~ 75 MPa (DIN EN ISO 527)

Tensile strength

~ 6,0 MPa (DIN EN ISO 527)

Elongation at break

~ 10% (DIN EN ISO 527)

Injection Equipment and Accessories

Well proven, 2 Component Injectionpump, air driven for Polyurethane and Silicate resins

Well proven, 2 Component Injectionpump, air driven for Polyurethane and Silicate resins

For grouting in soil, gravel

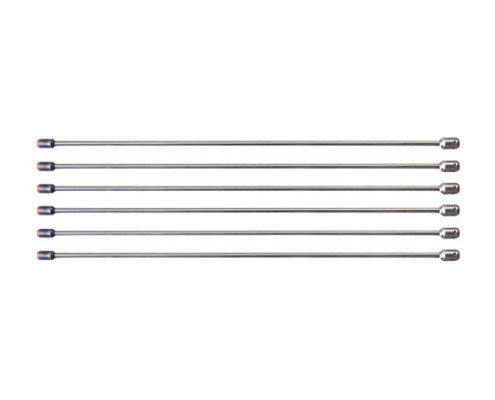

Piling Injection Spear

- Length 1000mm

- External G1/4″ thread

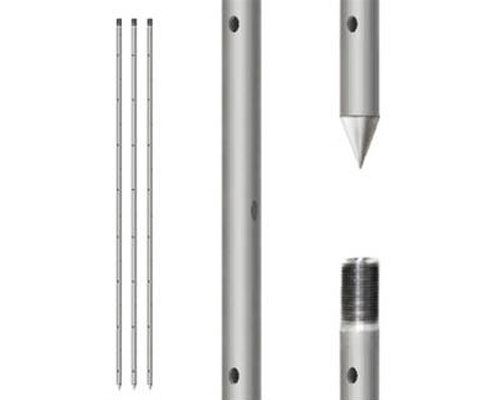

Piling Injection Spear HD

- Injection Pipe

- Length 1000mm

- Wall thickness 5mm

- OD 20mm