PROOFMATE RTX System

The PROOFMATE RTX SYSTEM is an exterior, strip-shaped waterproofing and connection system for sealing construction joints, predetermined crack cross-sections, building separation, construction and movement joints against pressing water.

It consists of a high-performance sealing tape based on flexible polyolefins (FPO) – the PROOFMATE GR tape – and the two-component, creamy epoxy resin-based PROOFMATE TX-S and TX-W system adhesives.

PROOFMATE GR Tape, which can be welded to conventional TPO/TPE/FPO plastic waterproofing membranes (KDB) and waterstops, can be used as an adhesive joint between structural components such as segments or cast-in-place concrete and plastic waterproofing membranes/waterstops.

The special material base and consistency of the PROOFMATE TX-S and PROOFMATE TX-W system adhesives enables them to be used even on matt damp substrates, as well as for safe processing in horizontal and vertical areas and even overhead.

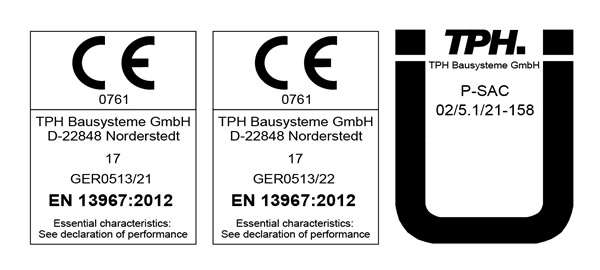

PROOFMATE GR Membrane

System component of the PROOFMATE RTX system. Sealing film based on flexible polyolefin (FPO).

- For sealing construction joints, predetermined crack cross-sections, building separation, construction and movement joints against pressing water

- Can be welded to conventional TPO/TPE/FPO plastic waterproofing membranes (KDB) and joint tapes

- Can also be used as an adhesive joint between structural elements, such as tubbings or cast-in-place concrete and plastic waterproofing membranes / waterstops

- Available thicknesses: 1 mm and 2 mm

- Available widths: 150, 200, 300 and 400 mm

~ 1830 g/m² (for 2 mm)

> 5 bar (for 2 mm)

transverse:~ 14 N/mm2 (DIN EN ISO 527-3)

transverse: ~ 1000 % (DIN EN ISO 527-3)

transverse: ~ 100 N (for 1 mm)

transverse: ~ 200 N (for 2mm)

at 25% elongation transverse approx. 3,0 N/mm

at 50% elongation transverse approx. 3.5 N/mm

(DIN EN ISO 527-3)

at 25% elongation transverse approx. 5.6 N/mm

at 50% elongation transverse approx. 6.5 N/mm

(DIN EN ISO 527-3)

PROOFMATE TX-S and PROOFMATE TX-W

System component of the PROOFMATE RTX system. 2-component EP-based adhesive and leveling filler.

- PROOFMATE TX-S is used at a component temperature of 15° to 30° C

- PROOFMATE TX-W is used at lower component temperatures

- Set particularly creamy and sticky

- Safe processing even overhead

- Can also be used on matt damp substrates

- Processing without primer

PROOFMATE TX-S

PROOFMATE TX-W

Accessories

Metal spatula

150mm

Hand press

Pneumatic hand press

For cleaning the substrate and binding dust and other impurities.

For priming on highly absorbent, dry substrates, such as weathered concrete, clinker, eternit, plaster, natural stone, etc.